TOP Tyre-Coupling

The world’s largest industrial coupling product portfolio provides elastic, high elasticity, torsional rigidity, fluid dynamics, gapless solutions and tyre couplings.

Services

Lorem ipsum dolor sit amet Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et

CH Tyre couplings provide all the desirable features of an ideal flexible coupling, including CH fixing. The CH Tyre coupling is a ‘torsionally elastic’ coupling offering versatility to designers and engineers with a choice of flange combinations to suit most applications.

Tire Coupling

Higher torque capacity – High misalignment bearing capacity i.e axial, parallel & angular – Dampens vibrations & torsional oscillations in drive – No lubrication required as there is no relative motion between coupling parts – Easy tyre replacement without dismantling driver or driven position – Available with taper bush facility in “F” & “H” type flanges – Easy installation requiring no special tools or skilled labour – Suitable to operate in robust environmental conditions

PA-40 Tyres Coupling

Tyres are available in natural rubber. The Tyre coupling is primarily designed to allow for misalignment both angular and parallel and compensates for end float. Torsional vibration is reduced and shock loads minimized by the flexing tyre. The coupling has been successfully subjected, under normal circumstances, to angular misalignment up to 4º, parallel misalignment up to 3mm and end float up to 8mm (on the larger sizes only).

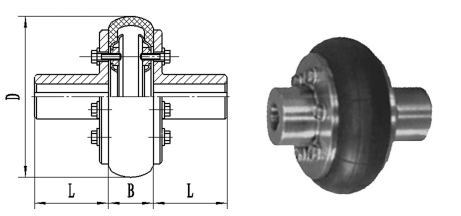

Tyre Flexible Shaft Coupling

The tyre coupling is a torsional elastic coupling, which is composed of two flanges with shaft holes and a rubber tire body.

CH tire coupling is an elastic coupling with high performance, because the elastic element is as a whole tire body, so tire coupling has good shock damping and the shaft offset compensation performance, absorbing excellent and convenient assembly and disassembly, no lubrication, easy maintenance,

Cast Iron tyre tire couplings

· material: cast iron GG25, GG20 steel: C45

· made up of 3 parts: 2 couplings and one tyre body.

· transmission torque:10-20000N.M

· Axial misalignment: D*2%

· Application: tire couplings are usually used in wet, dusty,udner attact, vibration,rotating and complex working condition. like: diesel pump

· Installation: easy on, easy off.

· Maintenance: no need for lubricating and durable.

Motor use shaft coupling flex tire coupling

1. Plastic components( tyres) and metal plates made into a whole by sulfur and felting. Connecting the 2 half-coupling directly by bolts when installing.

2. Flexibility, large damping, large compensation dosage.

3. Simple designing ,easy for assembling and disassembling. The tyres can be replaced without moving 2 half-coupling.

4. Disadvantage, large axial power will be brought on the driven end as the rotate angle increasing.

Steel Flexible Rubber Tyre Coupling

The tyre type coupling is divided into two types: convex type and concave type. The convex type is divided into three types: a skeleton type integral type, a boneless integral type and a radial cut type.

The inside of the tire ring is bonded to the steel skeleton by a vulcanization method, and a nut is welded to the bolt hole on the skeleton.

Highly flexible tyre coupling

CH Tyre Couplings are highly elastic, lubrication free couplings that tolerate large amounts of misalignment in all planes as well as offering simple installation and inspection without disrupting the drive. The CH coupling also has excellent shock absorbing properties while reducing vibration and torsional oscillations.

- Simple time saving installation – motor and machine remains undisturbed whilst tyre is changed

- Large misalignment capability, 4° angular, up to 6mm parallel and 8mm axial

- Internal load carrying cords are wound in both directions, so there is no problem on reversing drives

- Tyres are available in standard and FRAS (Fire Resistant Anti Static) construction. ATEX approved.

- Simple visual inspection to aid maintenance

- Taper Lock® and pilot bore flanges

- Lubrication free

- Pump spacer and flywheel fixing variants available

CH-COULING

THE LEADER OF COUPLING

A tyre coupling is an elastic coupling and consists of a flexible element—the tyre—and two coupling halves, also referred to as the hub or flange. The coupling half is made from cast iron and is available in both pre-drilled and clamping bush variants for quick installation and removal. In the latter case, the hub has a conical bore for the clamping bush.

The flexible element consists of a rubber composite as standard; this composite is suitable for a temperature range from -50°C to +50°C. The element is also available in a chloroprene variant, which meets the FRAS guidelines (fire-resistant and antistatic) and also has a greater resistance to oil and heat. This variant is suitable for a temperature range from -15°C to +70°C. To produce a complete ATEX-certified tyre coupling, the flexible FRAS-compliant element must be used together with coupling halves that have been specially modified for this purpose. Our product specialists can give you more detailed information on this.

Product Update

If you can’t find a product that suits you, you can refer to our daily product updates, or contact our professionals to provide customized products

Get In Touch

Hours

Mon – Fri: 10am – 9pm

Weekends: 10am – 3m